Haas connect

Author: k | 2025-04-24

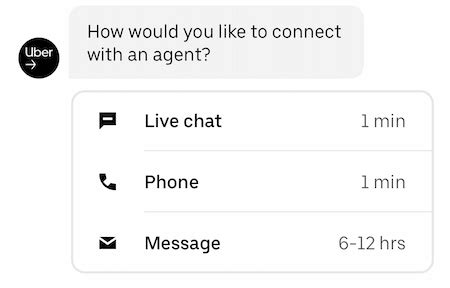

Both Haas Drop and Haas Connect can cause network issues, resulting in poor performance or loss of connection. To Disable Haas Connect: Press [SETTING]. Select the Network tab. Navigate to the Haas Connect sub-tab. Disable Haas Connect. To Disable Haas Drop: Press [SETTING]. HAAS NGC Networking - Haas Connect. metal-ica; ; Haas; Replies 836. Duc. D. N. Haas GR510 connected and was fine. Now it's not connecting and never connects even with the same settings. netshareissues; ; CNC Machining; Replies 186. netshareissues. N. S.

Connect with Bren Haas – Bren Haas Website

+10 FEED RATE An override key on the Haas control that increases the current feed rate in 10% increments. Together, -10 FEED RATE, +10 FEED RATE, and 100% FEED RATE allow an operator to make adjustments to tool feeds. +10 SPINDLE An override key on the Haas control that increases the current spindle speed in 10% increments. Together, -10 SPINDLE, +10 SPINDLE, and 100% SPINDLE allow an operator to make adjustments to spindle speeds. +A A jog key that rotates machine components around the A axis in the positive direction. Not all Haas mills are equipped with a fourth A axis. +X A jog key that moves the spindle along the X axis in the positive direction. +Y A jog key that moves the spindle along the Y axis in the positive direction. +Z A jog key that moves the spindle along the Z axis in the positive direction. -10 FEED RATE An override key on the Haas control that decreases the current feed rate in 10% increments. Together, -10 FEED RATE, +10 FEED RATE, and 100% FEED RATE allow an operator to make adjustments to tool feeds. -10 SPINDLE An override key on the Haas control that decreases the current spindle speed in 10% increments. Together, -10 SPINDLE, +10 SPINDLE, and 100% SPINDLE allow an operator to make adjustments to spindle speeds. 100% FEED RATE An override key on the Haas control that sets the feed rate back to 100% of the programmed value. Together, -10 FEED RATE, +10 FEED RATE, and 100% FEED RATE allow an operator to make adjustments to tool feeds. 100% RAPID An override key on the Haas control that allows the machine spindle to move at its maximum rate of travel. 100% SPINDLE An override key on the Haas control that sets the spindle

Connect and Calibrate Haas Robot - Haas Automation Inc.

High-speed wire EDM machines won the 26th Industrial Machinery Design Award.The A55 horizontal machining center model D received the 31st Japan Society for the Promotion of Machine Industry Award. The HYPER5 micromachining machine won the 16th Precision Engineering Society Technology Award. In 1999, the development of V33/SG2.3 set a new standard for high-speed machining. In 2001, the Hyper 2 ultra-precision machining center was launched, along with the MAG4 5-axis linear guide aerospace industry high-speed machining center.During 2003, the world’s first 0.02mm automatic threading ultra-precision wire EDM machine was developed.08. Grob from GermanyHeadquartered in Mindelheim, Germany, GROB is a globally renowned manufacturer of machine tools and production lines. From standard machine tools to complex production systems, cutting lines, assembly units, and fully automatic assembly lines, GROB’s technology and processes are always at the global forefront.GROB G550Grob China established its R&D center in 2017, laying a solid foundation for deeper product and technology innovations. With this commitment, it has been recognized as a “National High-Tech Enterprise.” Grob (China) holds about 75% market share in China’s automotive powertrain, serving well-known joint ventures like Beijing Benz, Brilliance BMW, SAIC General Motors, Volkswagen, Changan Ford, and national brands like Geely, Zotye, Haima, and Chery. Beyond the automotive industry, Grob China’s independently produced GA series five-axis universal machining centers GA350 and GA550, known for their quality, precision, and after-sales service, are increasingly favored in aerospace, tooling, machinery manufacturing, and other fields.09. HAAS from the USAHaas Automation is a CNC machine tool manufacturer based in Oxnard, California, with a factory area exceeding 100,000 square meters. Its CNC machine tools’ annual production reached over 12,500 units in 2006.Haas VF-6SS Vertical CNC Machining CenterSince its establishment, Haas has used the most modern production processes to ensure its machine tools’ cost-effectiveness. This approach has led to steady growth and continuous expansion of its production line. Haas regularly introduces innovative new machine tools to improve its existing line. In 2003, Haas set up its Asian headquarters in Shanghai, mainly supporting local HFO (Haas Factory Outlet) services for customers. The HFO network provides rapid local service and quick repair support when needed, keeping nearly 10,000 Haas machines across the country in good operating condition. Each HFO is equipped with a complete showroom, Haas-trained and certified service personnel, extensive spare parts inventory, and service vehicles on standby.When Gene Haas first introduced the Haas VF-1 vertical machining center, it established the standard for high-quality,WiFi Connection for the Haas Control - Haas Automation Inc.

Coolant nozzle to move one position lower. CLNT UP A jog key that causes the coolant nozzle to move one position higher. CNC controls A combination of software and hardware that directs the operation of a CNC machine. control keypad The main part of the Haas control panel consisting of nine areas of keys that allow an operator to input information into the Haas control. control panel The group of controls on a CNC machine that run, store, and edit the commands of a part program and other coordinate information. coolant A substance that is used to prevent a workpiece from reaching excessively high temperatures during machining. CURNT COMDS The display key on the Haas control that shows fifteen lines of the current program, modal program values, axis positions, and the position during runtime. cursor keys The group of keys in the center of the control keypad that allows an operator to move through various screens and fields in the control. Cursor keys also enable the edit and search function for CNC programs in addition to moving the cursor up, down, left, and right through the program or screen options. CW An override key on the Haas control that starts the spindle in the clockwise direction. CYCLE START The control button used to begin a program or continue a program that has been previously stopped. diagnostic Information that is vital to routine machine maintenance. Direct Numerical Control The direct control of CNC machines by a large central host computer. With DNC, the program is run directly from the memory of a host computer and is not stored in the memory of the machine's own control. display keys The area of the control keypad that allows the operator to show different information, such as offsets, machine settings, and the current program.. Both Haas Drop and Haas Connect can cause network issues, resulting in poor performance or loss of connection. To Disable Haas Connect: Press [SETTING]. Select the Network tab. Navigate to the Haas Connect sub-tab. Disable Haas Connect. To Disable Haas Drop: Press [SETTING]. HAAS NGC Networking - Haas Connect. metal-ica; ; Haas; Replies 836. Duc. D. N. Haas GR510 connected and was fine. Now it's not connecting and never connects even with the same settings. netshareissues; ; CNC Machining; Replies 186. netshareissues. N. S.Haas Robot - Connect to iPendant

Back to 100% of the programmed value. Together, -10 SPINDLE, +10 SPINDLE, and 100% SPINDLE allow an operator to make adjustments to spindle speed. 25% RAPID An override key on the Haas control that limits rapid traverse to 25% of maximum. 5% RAPID An override key on the Haas control that limits rapid traverse to 5% of maximum. 50% RAPID An override key on the Haas control that limits rapid traverse to 50% of maximum. -A A jog key that rotates machine components around the A axis in the negative direction. Not all Haas mills are equipped with a fourth A axis. Alarm 176 An alarm code on the Haas control that indicates the machine is experiencing an over-voltage condition. Alarm 176 initiates auto-shutdown after 4.5 minutes. Alarm 177 An alarm code on the Haas control that indicates the machine is experiencing an overheating condition. Alarm 177 initiates auto-shutdown after 4.5 minutes. ALARM/MESGS The display key on the Haas control that shows the current alarms when pressed once and messages when pressed twice. ALL AXES In ZERO RETURN mode, the key that returns and initializes all axes to machine zero. alpha keys The area of the control keypad that allows an operator to enter letters and special characters into the control. Auto Power Off Timer Setting 1. A setting that indicates how many minutes of idle time must lapse before the machine is automatically turned off. AUX CLNT A jog key that turns on the through-spindle coolant system when in MDI mode. Pressing this key again shuts off the system. axis An imaginary straight line or circle used to describe the location or movement of an object in three-dimensional space. An axis is used to indicate the direction of motion on CNC machines. block delete A machine control that providesConnect Your Haas Machine to the Internet - Haas Automation Inc.

The option of skipping a predetermined series of program blocks. A block delete allows the operator to run two versions of the same program. bracket [ ]. Punctuation marks used to separate CNC program commands from user comments. CANCEL A key on the Haas control that backspaces the cursor to delete the last character entered or cancels any program block that is highlighted during a block edit. CCW An override key on the Haas control that starts the spindle in the counterclockwise direction. CHC Classic Haas Control. A popular model of the Haas Automation®, Inc. CNC control. There have been several versions of the CHC since it was first released in 1988. chip auger A rotating shaft with a helical blade that removes chips from the machine. chip conveyor A movable belt that helps to remove chips from the machine. CHIP FWD A jog key that causes the chip auger to remove chips from the machine. CHIP REV A jog key that causes the chip auger to move in the opposite direction. CHIP STOP A jog key that causes the chip auger to stop. chips A small fragment of material that is removed from a workpiece during a cutting operation. Chips are the byproduct of machining. CIRCLE-CIRCLE TANGENT calculator A machining calculator that helps an operator calculate points of intersection between two circles or points. CIRCLE-LINE TANGENT calculator A machining calculator that helps an operator calculate points of intersection where a circle and a line meet as a tangent. CIRCULAR calculator A machining calculator that helps an operator solve problems involving circular motion. Classic Haas Control CHC. A popular model of the Haas Automation®, Inc. CNC control. There have been several versions of the CHC since it was first released in 1988. CLNT DOWN A jog key that causes theHaas Robot - iPendant Connect and Jog - Haas Automation Inc.

We are back again at the 17th Annual HTEC CNC Educator Conference, hosted this year at Dunwoody College of Technology in Minneapolis, Minnesota, from July 22-25, 2024.For over a decade, Haas Automation and its global network of Haas Factory Outlets have partnered with educational institutions at various levels to organize the Haas Technical Education Community (HTEC) conferences in North America and Europe. These events are crucial for educators to exchange knowledge on the best practices in teaching CNC machining, CAD, CAM, simulation, automation, metrology, and more.At HTEC 2024, we will be focusing on how CIMCO Edit 2024, Machine Simulation, CIMCO Probing and CIMCO Verify can help educators provide students with the essential knowledge needed for modern NC programming which includes simulation and verification through backplotting and machine simulation.As always, we’ll be more than happy to answer any of your questions and we look forward to speaking with you and showing how CIMCO software can benefit your institution.Be sure to come and visit our stand!More information:HTEC event informationCulture Connect Conference - Berkeley Haas

Next Gen Control Electrical - Service Manual 1 - NGC - Introduction 2 - NGC - Activation 3 - NGC - Software Update 4 - NGC - Firmware Update 5 - NGC - Configuration and Patch Files 6 - NGC - Error Report and Backup 7 - NGC - Main Processor 8 - NGC - I/O and TC PCB 9 - NGC - CAN Systems and Autodoor 10 - NGC - Servo Motors and Axis Cables 11 - NGC - 4th and 5th Axis 12 - NGC - Servo Amplifiers 13 - NGC - Vector Drive 14 - NGC - Regen 15 - NGC - 320V Power Supply 16 - NGC - Wye / Delta 17 - NGC - Circuit Breaker and Transformer 18 - NGC - PSUP PCB 19 - NGC - SKBIF and LCD Monitor 20 - NGC - Remote Jog Handle 21 - NGC - WorkLights and HIL 22 - NGC - CabCool 23 - NGC - MyHaas 24 - NGC - Networking 25 - NGC - 8M PCB 26 - NGC - Robot and Automation 27 - NGC - Machine Data Collection 28 - NGC - Control Icons 29 - NGC - Sensors and Switches 30 - NGC - USB 31 - NGC - Keypad 32 - NGC - Broken Tool Detection MyHaas - Installation MyHaas - Machine Registration MyHaas - Administration MyHaas - Mobile Application MyHaas - Troubleshooting MYHAAS - HaasDrop What Is MyHaas? The MyHaas application is used for monitoring and sending files to NGC Haas machines.Machine Requirements:Software version 100.19.000.1301 or higher.Wireless Networking Option. How to connect Haas machine to a network.Mobile Device Requirements:iOSiOS 13 or above.Wi-Fi connectivity.AndroidAndroid 8.0 or above.Wi-Fi connectivity.Download linksiOS: here. Android: here. Troubleshooting On the Machine Press [SETTING].Select the Network tab.Select the MyHaas sub-tab.Press [F1].Press [ENTER] to accept the disclaimer.The MyHaas screen shows the machine serial number and a PIN code. Record these numbers. On the MyHaas Website Log in to MyHaas.Put your mouse cursor over My Machines and click Add New Machine. Fill in the fields with the machine serial number, PIN code, and a nickname. A descriptive nickname. Both Haas Drop and Haas Connect can cause network issues, resulting in poor performance or loss of connection. To Disable Haas Connect: Press [SETTING]. Select the Network tab. Navigate to the Haas Connect sub-tab. Disable Haas Connect. To Disable Haas Drop: Press [SETTING]. HAAS NGC Networking - Haas Connect. metal-ica; ; Haas; Replies 836. Duc. D. N. Haas GR510 connected and was fine. Now it's not connecting and never connects even with the same settings. netshareissues; ; CNC Machining; Replies 186. netshareissues. N. S.

RESULTS FOR HAAS CONNECT TO NETWORK - American

What’s Happening?The 2025 NASCAR Cup Series roster is slowly coming together. Many teams made major moves as early as May 2024. However, a couple of teams still have some options on the table. Make sure to check this page prior to the start of the 2025 season to keep up with the latest changes, moves, and additions. read more…This article will be updated as drivers, teams, promotions, and demotions continue to happen throughout 2024 and into 2025.Familiar Faces in New Places:Noah Gragson – No. 4 – Front Row Motorsports (Formerly Stewart-Haas Racing)Justin Haley – No. 7 – Spire Motorsports (Formerly Rick Ware Racing)Chase Briscoe – No. 19 – Joe Gibbs Racing (Formerly Stewart-Haas Racing)Josh Berry – No. 21 – Wood Brothers Racing (Formerly Stewart-Haas Racing)Zane Smith – No. 38 – Front Row Motorsports (Formerly Spire Motorsports)Cody Ware – No. 51 – Rick Ware Racing (Formerly Part-Time)Ryan Preece – No. 60- RFK Racing (Formerly Stewart-Haas Racing)Michael McDowell – No. 71 – Spire Motorsports (Formerly Front Row Motorsports)Xfinity to Cup:A.J. Allmendinger – No. 16 – Kaulig RacingRiley Herbst – No. 35 – 23XI RacingCole Custer – No. 41 – Haas Factory TeamShane Van Gisbergen – No. 88 – Trackhouse RacingTrucks to Cup:Ty Dillon – No. 10 – Kaulig RacingTeams Not Returning From 2024:Stewart-Haas Racing (Distributing Three Charters)Rick Ware Racing – No 15 (Leased to RFK Racing)Teams Debuting in 2025:Front Row Motorsports – No. 423XI Racing – No. 35Haas Factory Team – No. 41RFK Racing – No. 60Trackhouse Racing – No. 88 Drivers Leaving the Cup Series Following 2024:Martin Truex Jr. – Formerly No. 19 – Joe Gibbs Racing – RetiringHarrison Burton – Formerly No. 21 – Wood Brothers Racing – Xfinity SeriesDaniel Hemric – Formerly the No. 31 – Kaulig Racing – Truck SeriesNo. 1 – Ross Chastain – Trackhouse RacingRoss Chastain returns to Trackhouse Racing for his fourth season. Chastain did not have as great a season at Trackhouse Racing as he had in the past. Chastain missed out on the Playoffs for the first time since joining Trackhouse in 2022.No. 2 – Austin Cindric – Team PenskeAustin Cindric had a solid 2024, making the 2024 NASCAR Cup Series Playoffs. However, following his stellar time in the NASCAR Xfinity Series, Cindric has yet to live up to the once-high hopes Penske had for him.No. 3 – Austin Dillon – Richard Childress RacingAustin Dillon’s rollercoaster saga following his win at Richmond Raceway made a very difficult 2024 for RCR even worse. Dillon will try to rebound in 2025. However, the aging veteran is coming off his worst statistical season since his debut in 2014.No. 4 – Noah Gragson – Front Row MotorsportsOne season after losing his full-time ride with Legacy Motor Club, Noah Gragson made the best of his time in the No. 10 at Stewart-Haas Racing. Now, Gragson joins a new team, Front Row Motorsports. As he continues to find rides in NASCAR, the question continues: Will Gragson be the driver he most hoped he would be?No. 5 – Kyle LarsonInstallation - Electrical Connection - Haas Automation

Display keys are located in the top center of the control keypad. display screen The main screen of the machine that displays important information for the operator. EDIT An operation mode key that allows manual editing of a program or the creation of new program in memory. EMERGENCY STOP E-stop. Used for emergencies only, the control button that automatically shuts down all machine functions. END A cursor arrow key that moves quickly to the end of a program or moves to the bottom of most displays. EOB End-of-Block. A key on the Haas control that signals the end of a program block. EOB is represented by a semicolon on the display screen. E-stop Emergency stop. Used for emergencies only, the control button that automatically shuts down all machine functions. feed The rate at which the cutting tool and the workpiece move in relation to one another. FEED HOLD The control button used to pause a program. FEED HOLD pauses tool feed but does not stop spindle movement. function keys The area of the control keypad that allows an operator to perform different functions depending on which display and mode are selected. Function keys are located in the top left corner of the control keypad. HAND CNTRL FEED An override key on the Haas control that allows the operator to adjust the programmed feed rate in 1% increments using the HANDLE. HAND CNTRL SPIN An override key on the Haas control that allows the operator to adjust spindle speed in 1% increments using the HANDLE. HAND JOG An operation mode key that allows for the manual operation of tool movement via the dial or jog buttons. HANDLE A rotating knob on the Haas control panel that moves the machine components along the axes. The handle "clicks" in controlled, measured increments that. Both Haas Drop and Haas Connect can cause network issues, resulting in poor performance or loss of connection. To Disable Haas Connect: Press [SETTING]. Select the Network tab. Navigate to the Haas Connect sub-tab. Disable Haas Connect. To Disable Haas Drop: Press [SETTING].Haas Robot - HMI IPendant Connect

Wear, and other variables. operation mode keys The area of the control keypad that allows an operator to choose a particular operating mode, which in turn determines what tasks the machine will perform. overrides The group of keys in the lower left of the control keypad that adjust a programmed speed or feed rate by a certain percentage during operation. PAGE DOWN A cursor arrow key that moves one page down in the displays or moves down one program page. PAGE UP A cursor arrow key that moves one page up in the displays or moves up one program page. PARAM/DGNOS The display key on the Haas control that shows machine parameters when pressed once and diagnostics when pressed twice. parameters The limits or physical properties that determine function and operation of a CNC machine. parentheses ( ). Curved brackets used to separate program text information from CNC program commands. part program A series of instructions used by a CNC machine to perform the necessary sequence of operations to machine a specific workpiece. PART ZERO SET A function key that is used to automatically enter work coordinate offsets during part setup. POSIT The display key on the Haas control that brings up different pages listing machine axis positions of the spindle. power down The act of turning off the machine. POWER OFF The red button on the upper left of the Haas control panel that shuts off power to the machine. Power Off at M30 Setting 2. A setting that powers down a machine when the program reaches an M30 code. POWER ON The green button on the upper left of the Haas control panel that provides power to the machine. power up The act of turning on the machine. POWER UP/RESTART A reset key that automatically initializes the machineComments

+10 FEED RATE An override key on the Haas control that increases the current feed rate in 10% increments. Together, -10 FEED RATE, +10 FEED RATE, and 100% FEED RATE allow an operator to make adjustments to tool feeds. +10 SPINDLE An override key on the Haas control that increases the current spindle speed in 10% increments. Together, -10 SPINDLE, +10 SPINDLE, and 100% SPINDLE allow an operator to make adjustments to spindle speeds. +A A jog key that rotates machine components around the A axis in the positive direction. Not all Haas mills are equipped with a fourth A axis. +X A jog key that moves the spindle along the X axis in the positive direction. +Y A jog key that moves the spindle along the Y axis in the positive direction. +Z A jog key that moves the spindle along the Z axis in the positive direction. -10 FEED RATE An override key on the Haas control that decreases the current feed rate in 10% increments. Together, -10 FEED RATE, +10 FEED RATE, and 100% FEED RATE allow an operator to make adjustments to tool feeds. -10 SPINDLE An override key on the Haas control that decreases the current spindle speed in 10% increments. Together, -10 SPINDLE, +10 SPINDLE, and 100% SPINDLE allow an operator to make adjustments to spindle speeds. 100% FEED RATE An override key on the Haas control that sets the feed rate back to 100% of the programmed value. Together, -10 FEED RATE, +10 FEED RATE, and 100% FEED RATE allow an operator to make adjustments to tool feeds. 100% RAPID An override key on the Haas control that allows the machine spindle to move at its maximum rate of travel. 100% SPINDLE An override key on the Haas control that sets the spindle

2025-04-01High-speed wire EDM machines won the 26th Industrial Machinery Design Award.The A55 horizontal machining center model D received the 31st Japan Society for the Promotion of Machine Industry Award. The HYPER5 micromachining machine won the 16th Precision Engineering Society Technology Award. In 1999, the development of V33/SG2.3 set a new standard for high-speed machining. In 2001, the Hyper 2 ultra-precision machining center was launched, along with the MAG4 5-axis linear guide aerospace industry high-speed machining center.During 2003, the world’s first 0.02mm automatic threading ultra-precision wire EDM machine was developed.08. Grob from GermanyHeadquartered in Mindelheim, Germany, GROB is a globally renowned manufacturer of machine tools and production lines. From standard machine tools to complex production systems, cutting lines, assembly units, and fully automatic assembly lines, GROB’s technology and processes are always at the global forefront.GROB G550Grob China established its R&D center in 2017, laying a solid foundation for deeper product and technology innovations. With this commitment, it has been recognized as a “National High-Tech Enterprise.” Grob (China) holds about 75% market share in China’s automotive powertrain, serving well-known joint ventures like Beijing Benz, Brilliance BMW, SAIC General Motors, Volkswagen, Changan Ford, and national brands like Geely, Zotye, Haima, and Chery. Beyond the automotive industry, Grob China’s independently produced GA series five-axis universal machining centers GA350 and GA550, known for their quality, precision, and after-sales service, are increasingly favored in aerospace, tooling, machinery manufacturing, and other fields.09. HAAS from the USAHaas Automation is a CNC machine tool manufacturer based in Oxnard, California, with a factory area exceeding 100,000 square meters. Its CNC machine tools’ annual production reached over 12,500 units in 2006.Haas VF-6SS Vertical CNC Machining CenterSince its establishment, Haas has used the most modern production processes to ensure its machine tools’ cost-effectiveness. This approach has led to steady growth and continuous expansion of its production line. Haas regularly introduces innovative new machine tools to improve its existing line. In 2003, Haas set up its Asian headquarters in Shanghai, mainly supporting local HFO (Haas Factory Outlet) services for customers. The HFO network provides rapid local service and quick repair support when needed, keeping nearly 10,000 Haas machines across the country in good operating condition. Each HFO is equipped with a complete showroom, Haas-trained and certified service personnel, extensive spare parts inventory, and service vehicles on standby.When Gene Haas first introduced the Haas VF-1 vertical machining center, it established the standard for high-quality,

2025-04-04Back to 100% of the programmed value. Together, -10 SPINDLE, +10 SPINDLE, and 100% SPINDLE allow an operator to make adjustments to spindle speed. 25% RAPID An override key on the Haas control that limits rapid traverse to 25% of maximum. 5% RAPID An override key on the Haas control that limits rapid traverse to 5% of maximum. 50% RAPID An override key on the Haas control that limits rapid traverse to 50% of maximum. -A A jog key that rotates machine components around the A axis in the negative direction. Not all Haas mills are equipped with a fourth A axis. Alarm 176 An alarm code on the Haas control that indicates the machine is experiencing an over-voltage condition. Alarm 176 initiates auto-shutdown after 4.5 minutes. Alarm 177 An alarm code on the Haas control that indicates the machine is experiencing an overheating condition. Alarm 177 initiates auto-shutdown after 4.5 minutes. ALARM/MESGS The display key on the Haas control that shows the current alarms when pressed once and messages when pressed twice. ALL AXES In ZERO RETURN mode, the key that returns and initializes all axes to machine zero. alpha keys The area of the control keypad that allows an operator to enter letters and special characters into the control. Auto Power Off Timer Setting 1. A setting that indicates how many minutes of idle time must lapse before the machine is automatically turned off. AUX CLNT A jog key that turns on the through-spindle coolant system when in MDI mode. Pressing this key again shuts off the system. axis An imaginary straight line or circle used to describe the location or movement of an object in three-dimensional space. An axis is used to indicate the direction of motion on CNC machines. block delete A machine control that provides

2025-03-26